Contributing to a Recycling-Oriented Society

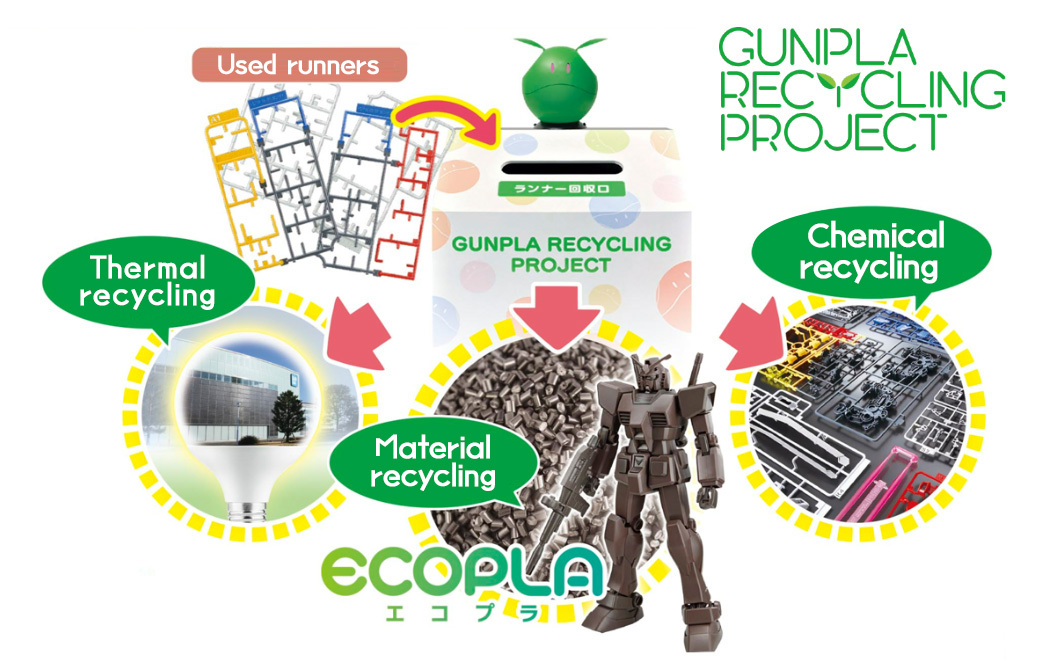

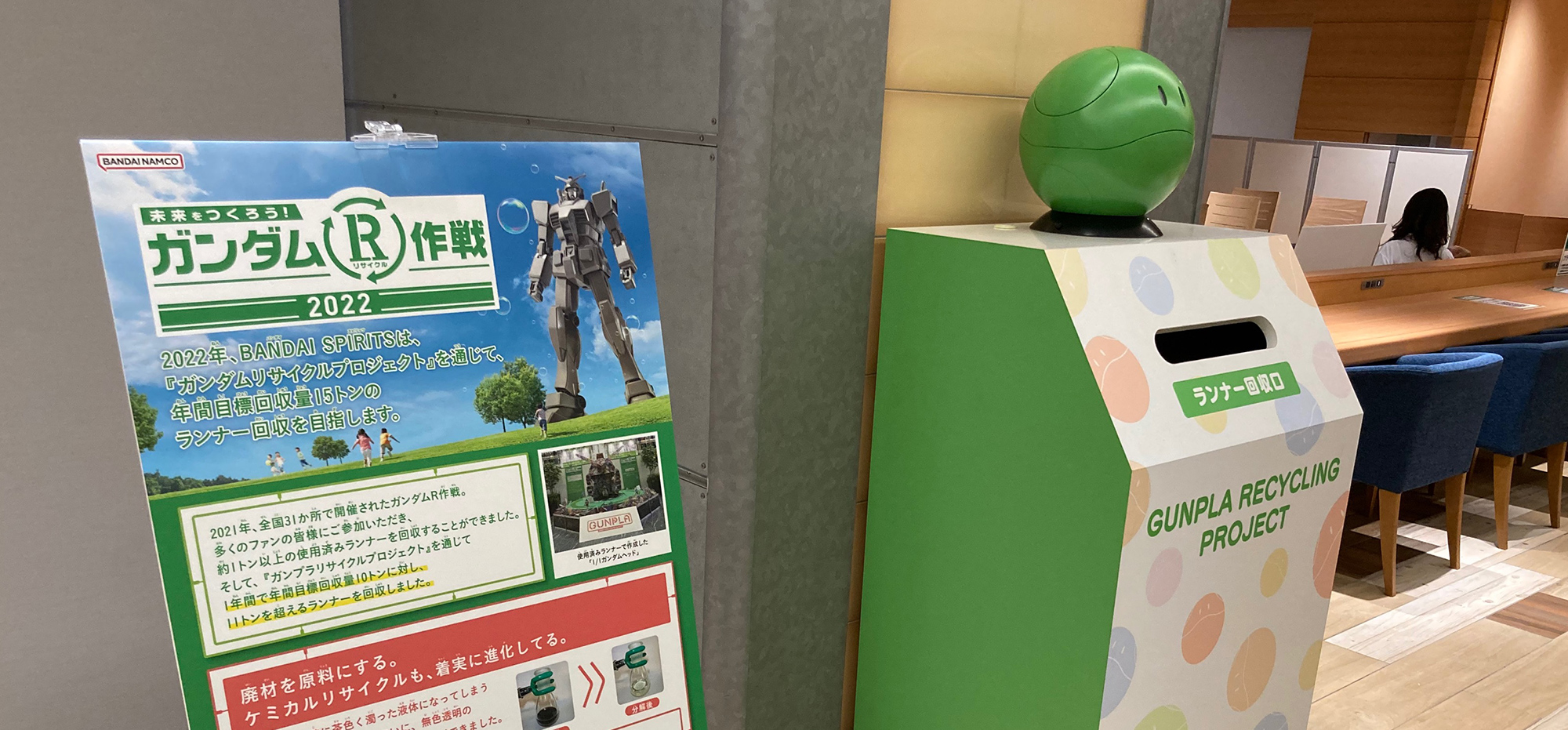

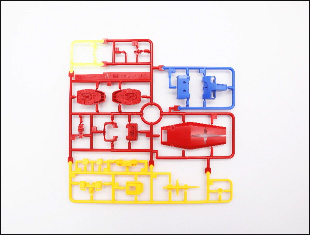

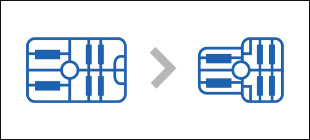

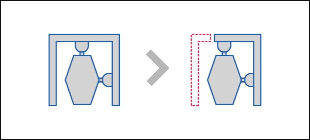

Used runners are collected from fans by installing collection boxes at approximately 200 directly amusement facilities operated by Bandai Namco Amusement. Bandai Logipal trucks that transport amusement prizes to facilities bring back runners on their return trips, thereby reducing the environmental impact of transportation.

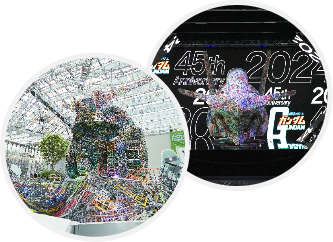

With the help of our fans, we collected about 11 tons of runners in the 2021 fiscal year, and we collected about 21 tons in the 2022 fiscal year.

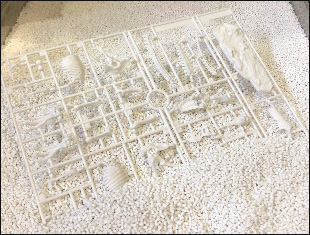

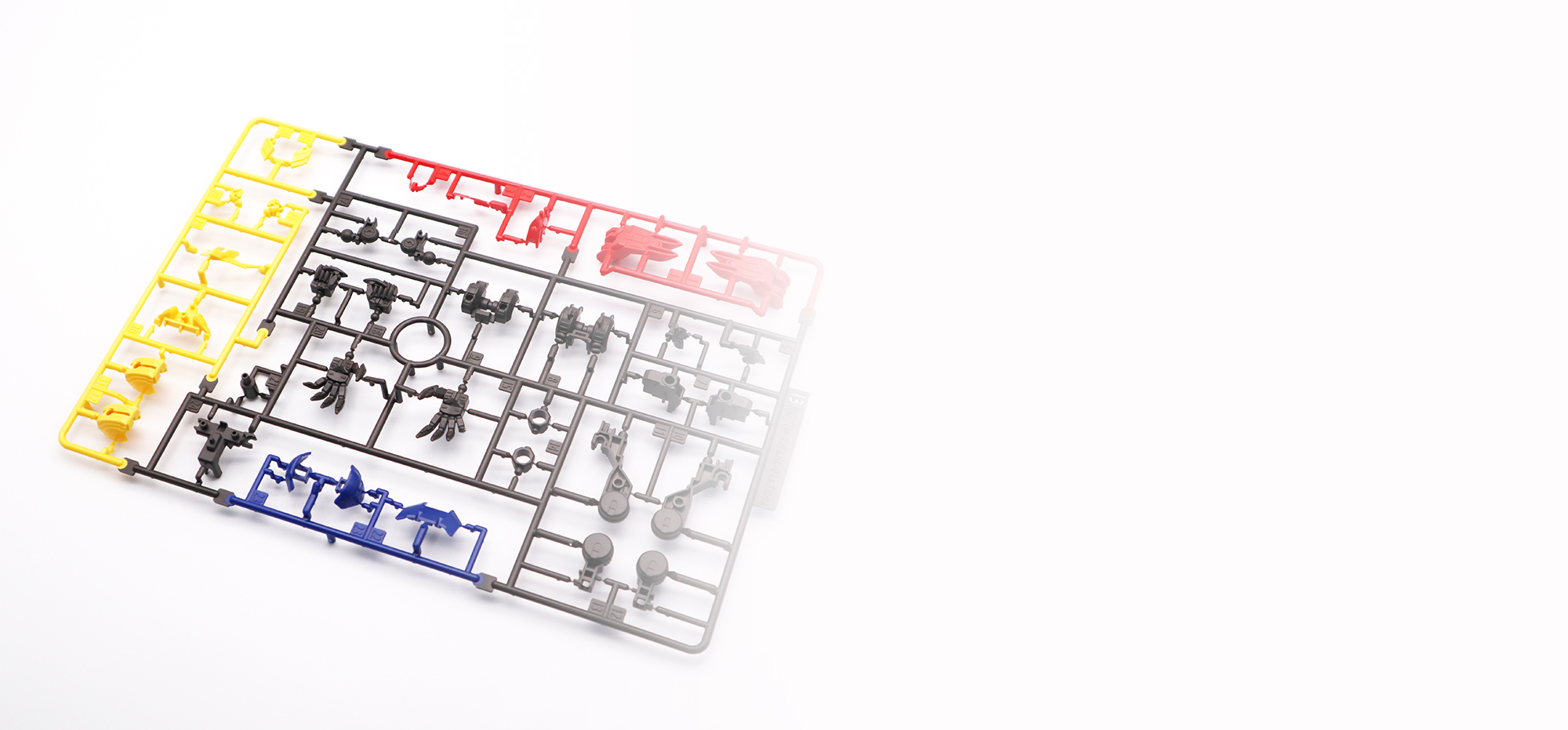

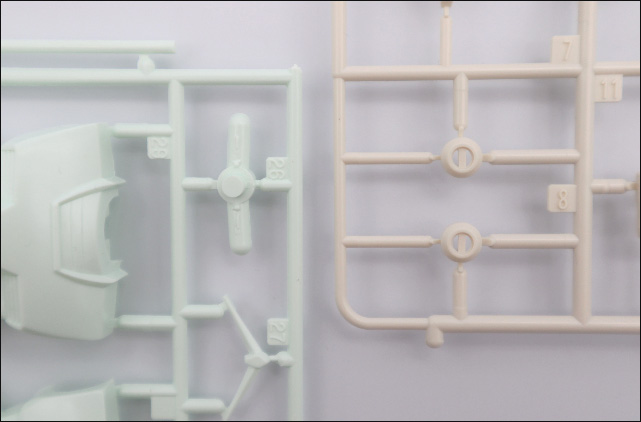

The collected runners, together with plastic waste from the plastic model production process, are partially reused as materials for demonstration experiments to realize chemical recycling, and the rest is reused through material and thermal recycling.

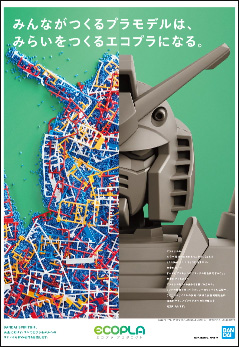

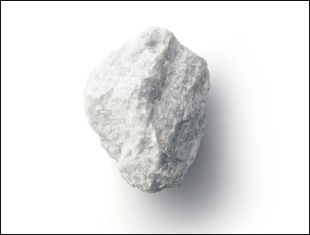

Material recycling is a recycling method in which used plastics are crushed, melted, and solidified for reuse. "ECOPLA" are products that make use of this recycled material.

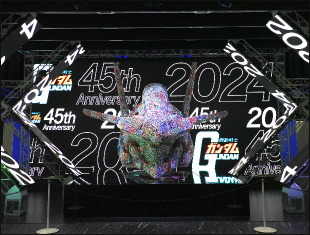

At an event titled Operation Gundam R (Recycle), we distribute ECOPLA and conduct activities to raise awareness about recycling through Gundam and Gunpla by offering visitors the opportunity to experience everything from assembly to collection.

Yukio

Matsuhashi

Deputy General Manager,

Global Business Department

and Creation Department,

Hobby Division

BANDAI SPIRITS

CO., LTD.

Thoughts on the Gunpla Recycling Project

How we will use our limited resources going forward is an important issue for us. Through the Gunpla Recycling Project, we recycle plastic model runners to be used as a resource to allow fans to enjoy our products sustainably.

View more

MOVIE

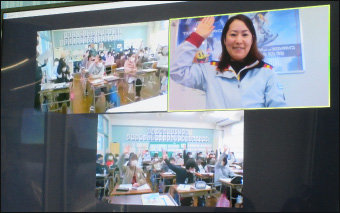

Gunpla-kun, a character designed to communicate the fun of plastic models, explains how the Gunpla Recycling Project works. The videos are used in“Gunpla Academia” classes.

View more

(4 minutes)

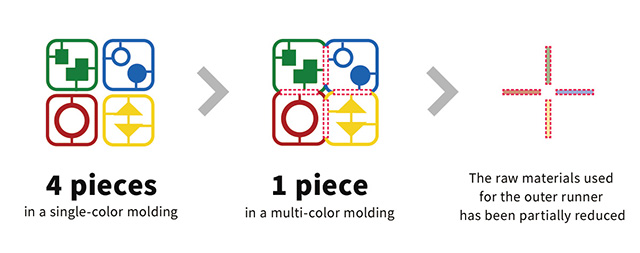

Development of Environmentally Friendly

Materials and Technologies

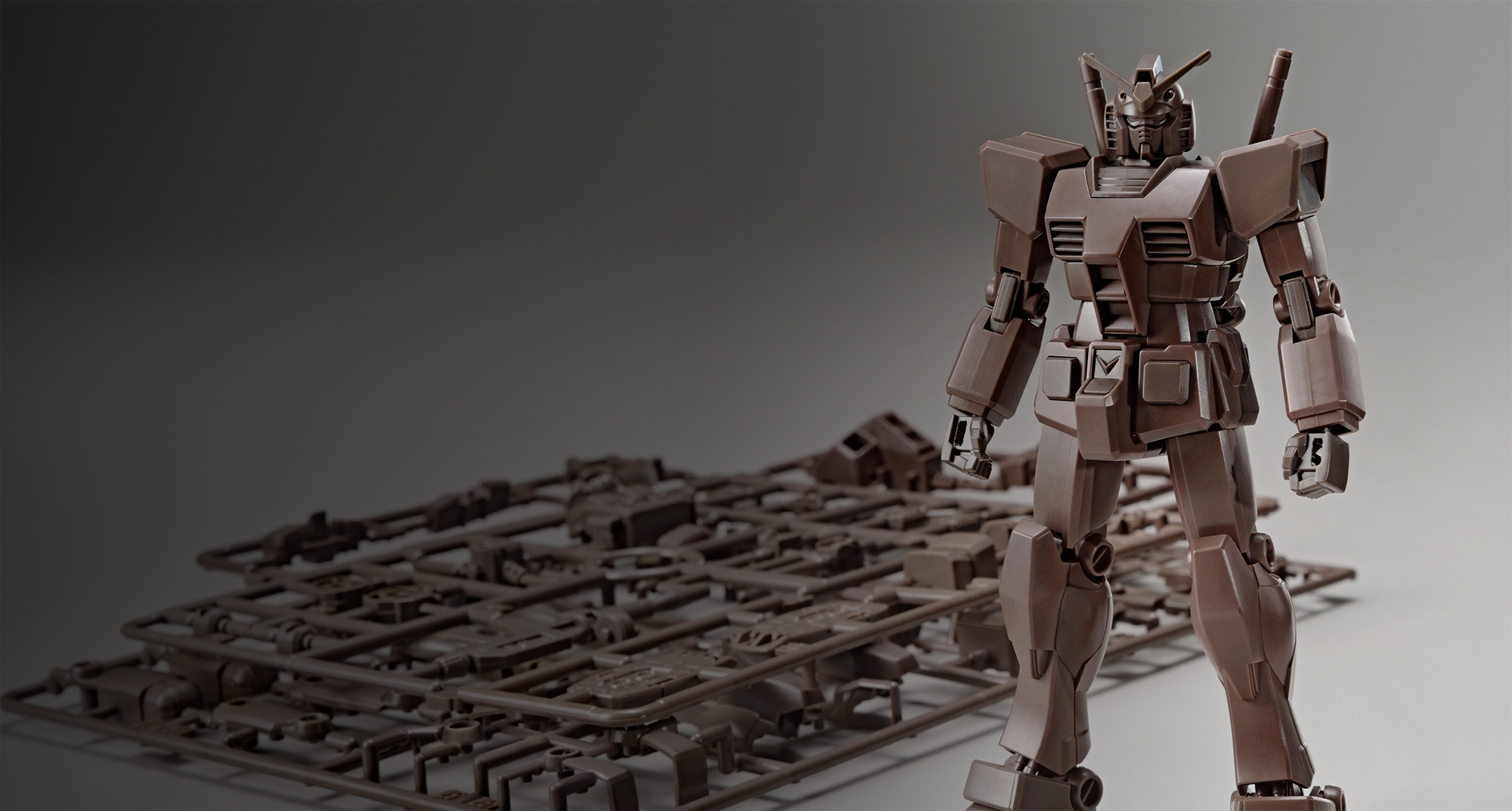

Introducing the first Gunpla

made from eggshell plastic

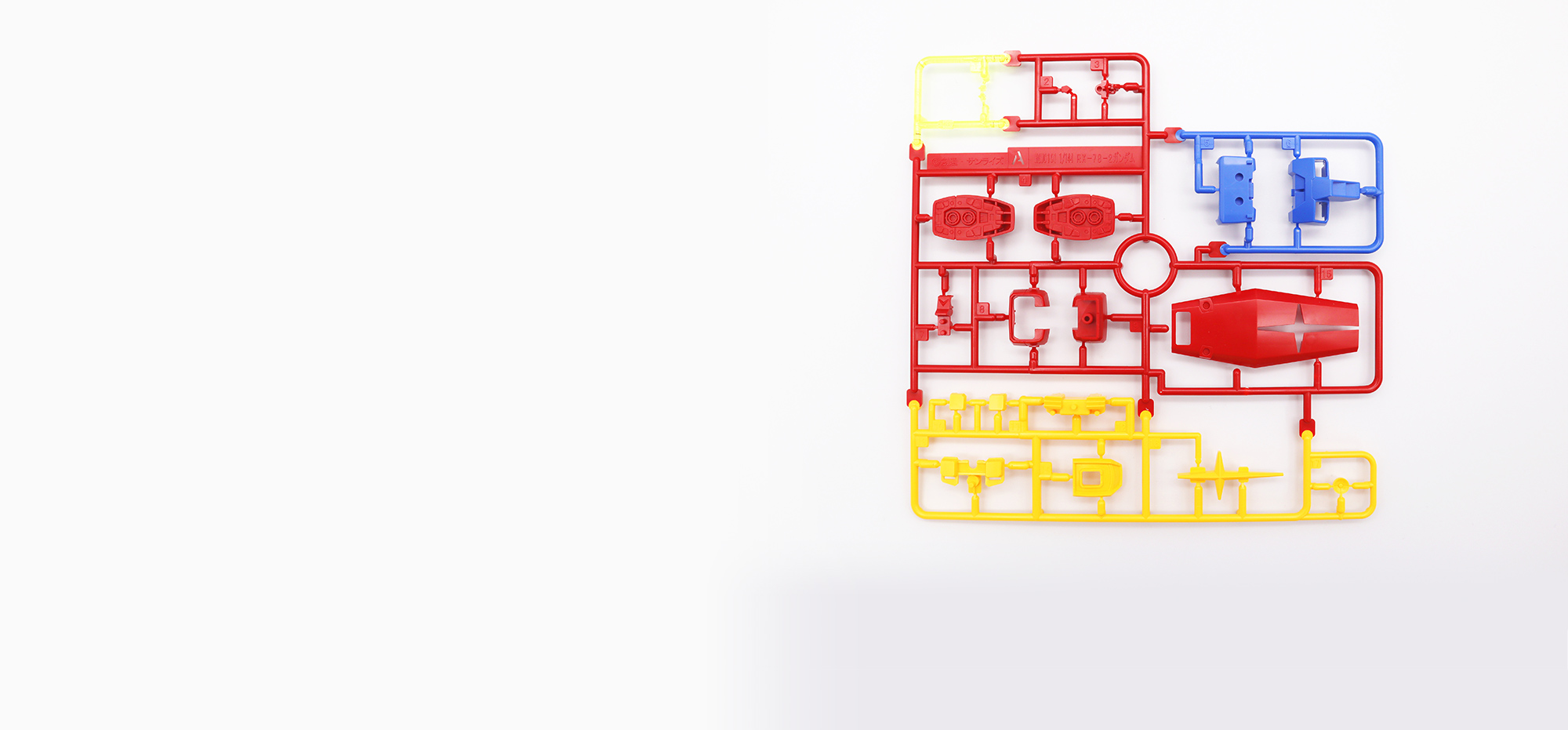

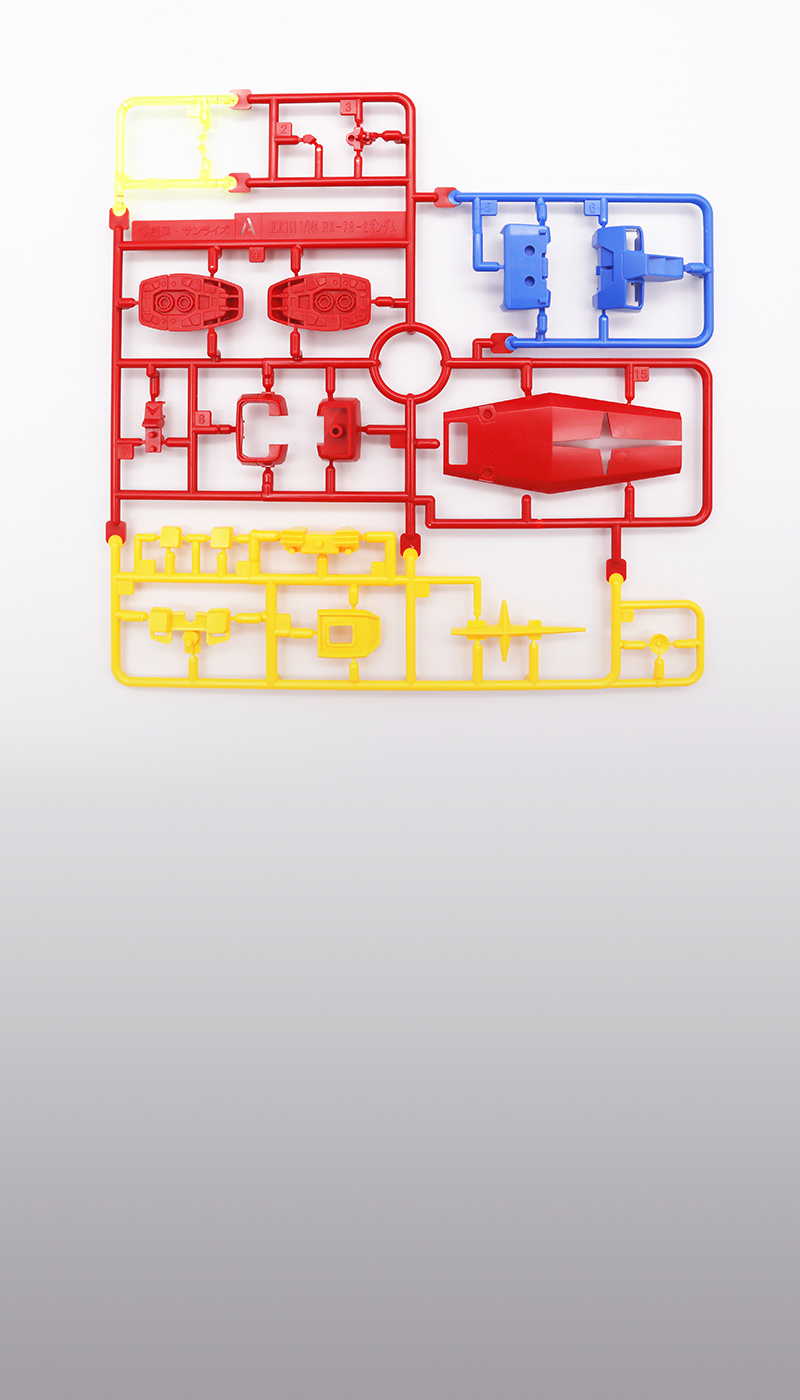

Eggshell plastic is a new material made partly from eggshells, which are generated as industrial waste. We combine polystyrene resin and bio-derived (biomass) materials to reduce the percentage of petroleum-derived plastics we use.

GUNDAM NEXT FUTURE LIMITED ENTRY GRADE

1/144 RX-78-2 GUNDAM [CLASSIC COLOR]

*This is an event-exclusive product.

[What is Classic Color?]

Classic Color refers to a warm, classical coloring that makes the most of the color of the molding itself, which is born from the cycle.

Education and Awareness Initiatives

The educational objectives of “Gunpla Academia”

■Using plastic models as subjects, students learn about factory production processes and the development of the latest advanced technologies.

■Students learn about the efforts of people involved in the production of plastic models and their work ethic.

■Students are given the opportunity to develop their own ideas about problems and solutions around sustaining high-quality manufacturing technology in the future.

| Target Audience | Fifth grade students at elementary schools(fourth and sixth grade students can also participate) |

| Subjects | Social Studies—Industrial Production in Japan (5th grade), integrated learning time/special activities, as part of learning about the SDGs |

| Teaching Materials | Teaching plan, videos, plastic model for assembly experience, etc. (all free of charge) |

| Hours | Pre-lesson (45 minutes × 2 periods), main lesson (45 minutes × 1 period), enrichment lesson (45 minutes × 1 period or more) |

Improving and Passing On Skills

Environmentally-Friendly,

Domestic, Self-Owned Factories

Reuse system for rainwater and well water

Bandai Hobby Center’s facilities2,000 tons of rainwater recycled annually through water storage and filtration

At the rainwater storage facility located under the plant, which has a storage capacity of 2 tons, stored rainwater and well water are filtered through a purification system and reused in the plant's toilets as washing water. As a result, approximately 2,000 tons of water is reused annually.

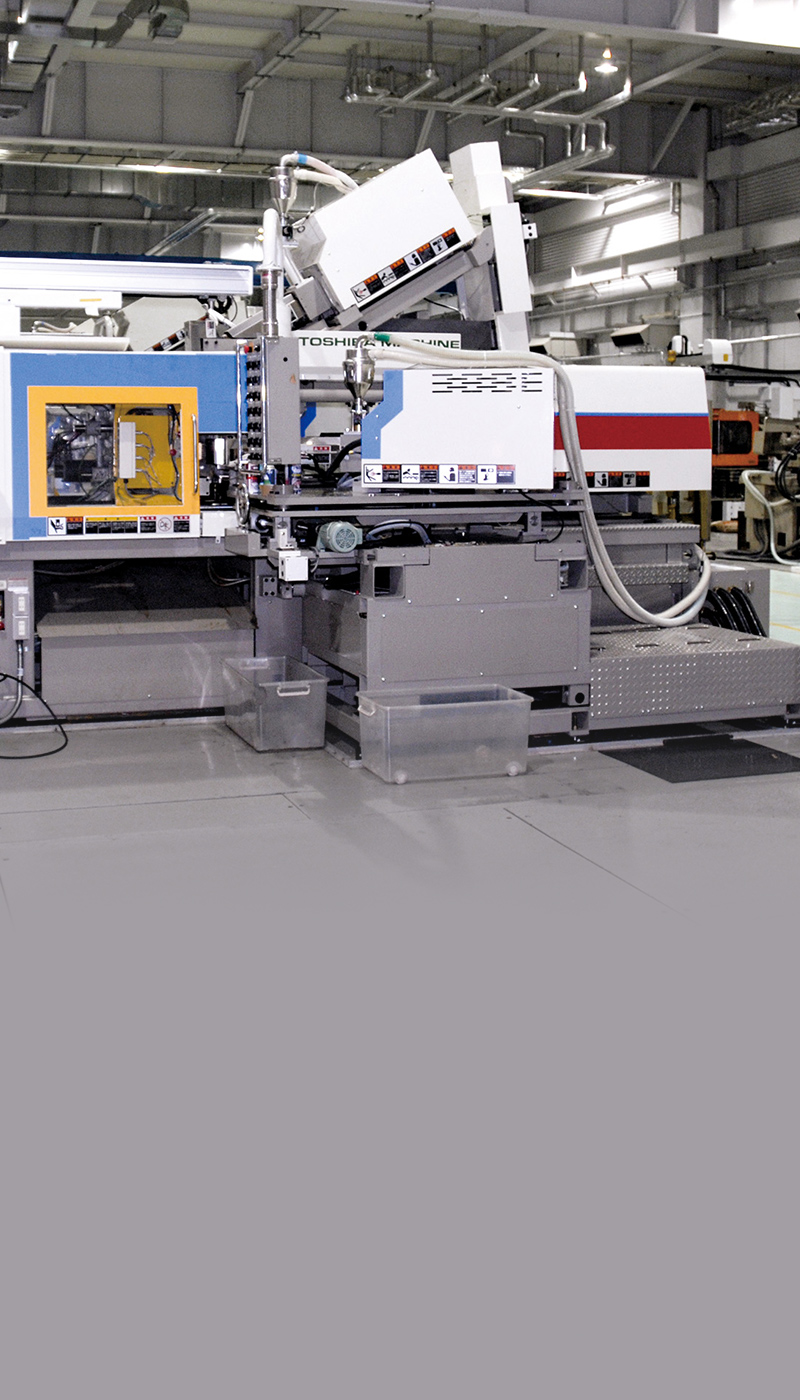

The Bandai Hobby Center pursues the evolution of plastic model technology and continues its environmental efforts.

Reduction of Packaging Material

Optimization of packaging

for figure products

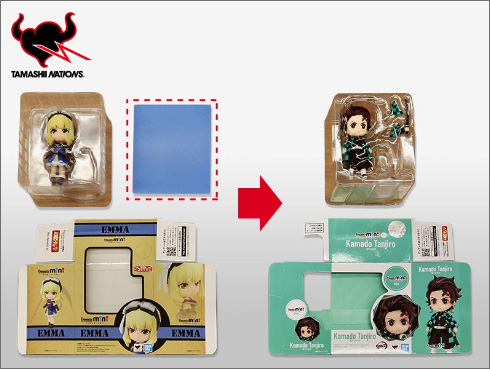

We have reexamined the use of clear plastic blisters (PET) as cushioning material for figures such as the Ichibankuji and are now actively switching to cardboard packaging.

Change in specifications of Ichibankuji figure packages

For some figure products, we are working to reduce the amount of paper used in instruction manuals by printing instructions directly on the packaging. In addition, the backing paper design that forms a background for the figure inside the package is printed directly on the package to reduce the amount of paper used.

Package with instructions printed directly

A product with the background design printed directly on the box without the backing paper

Manufacturing with Consideration

for Safety and Security

Strict implementation of quality standards

In order to provide safe and reliable products and services to fans, we have established a number of quality standards related to safety, performance, and labeling, which we continue to strictly enforce. We are also actively working to implement these standards globally.

Measures for safety and security at the production stage

In addition to inspections prior to mass production, we conduct inspections prior to factory shipment and product acceptance inspections at our partner plants in Japan and overseas. We strive to maintain and improve product quality by conducting multiple inspections for each process.

We also conduct ongoing plant audits at the final packaging plants where our products are manufactured. In addition to maintenance work and environment checks of facilities, we conduct regular checks of a wide range of items, including management systems for equipment, products and materials, and the working environment.

Inspections prior to shipment from the plant

Checking the operation of a needle detector

Checking the management

of tools and equipment

Updated June 2023

ECOPLA