BANDAI SPIRITS

STORY

Building Plastic Models and Future Workers — Passion Behind a Factory that Fascinates

August 20, 2025

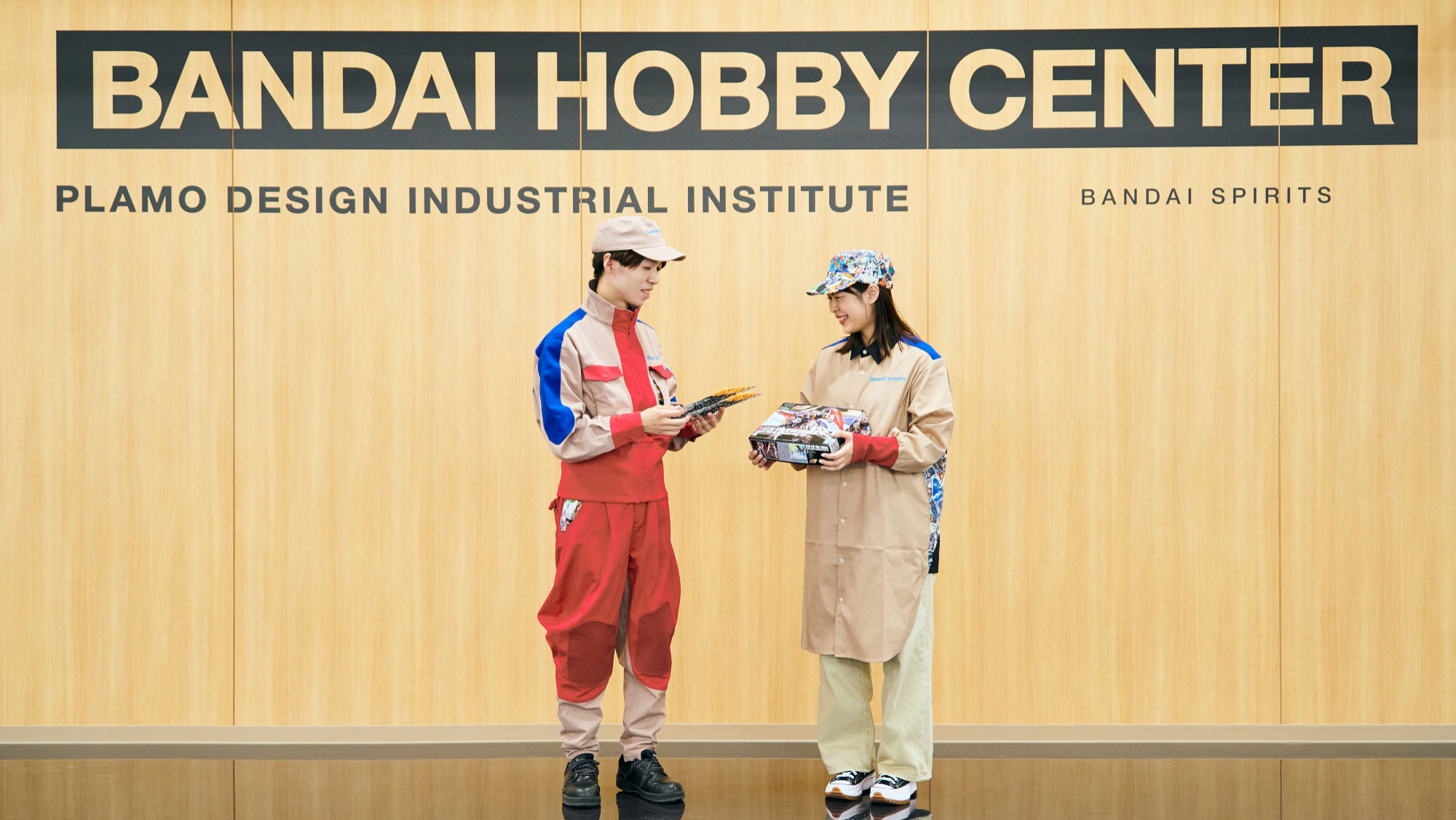

At the Bandai Hobby Center (BHC), a plastic model production complex in Shizuoka Prefecture, a new factory named the Bandai Hobby Center Plamo Design Industrial Institute (BHC PDII, read "Bandai Hobby Center PD two") commenced operations on July 24, 2025.

The concept of the new facility is to be a “factory that fascinates.” Complete with a museum where visitors can observe the process of producing plastic models, the facility will serve as a base for conveying the appeal of manufacturing from Shizuoka to the world.

This feature tells the story of the birth of BHC PDII in two parts. The first part covers the concept of a “factory that fascinates.” What does a factory that captivates and is loved by fans and employees look like? Here, we showcase the passion of project members who were involved from the concept creation phase.

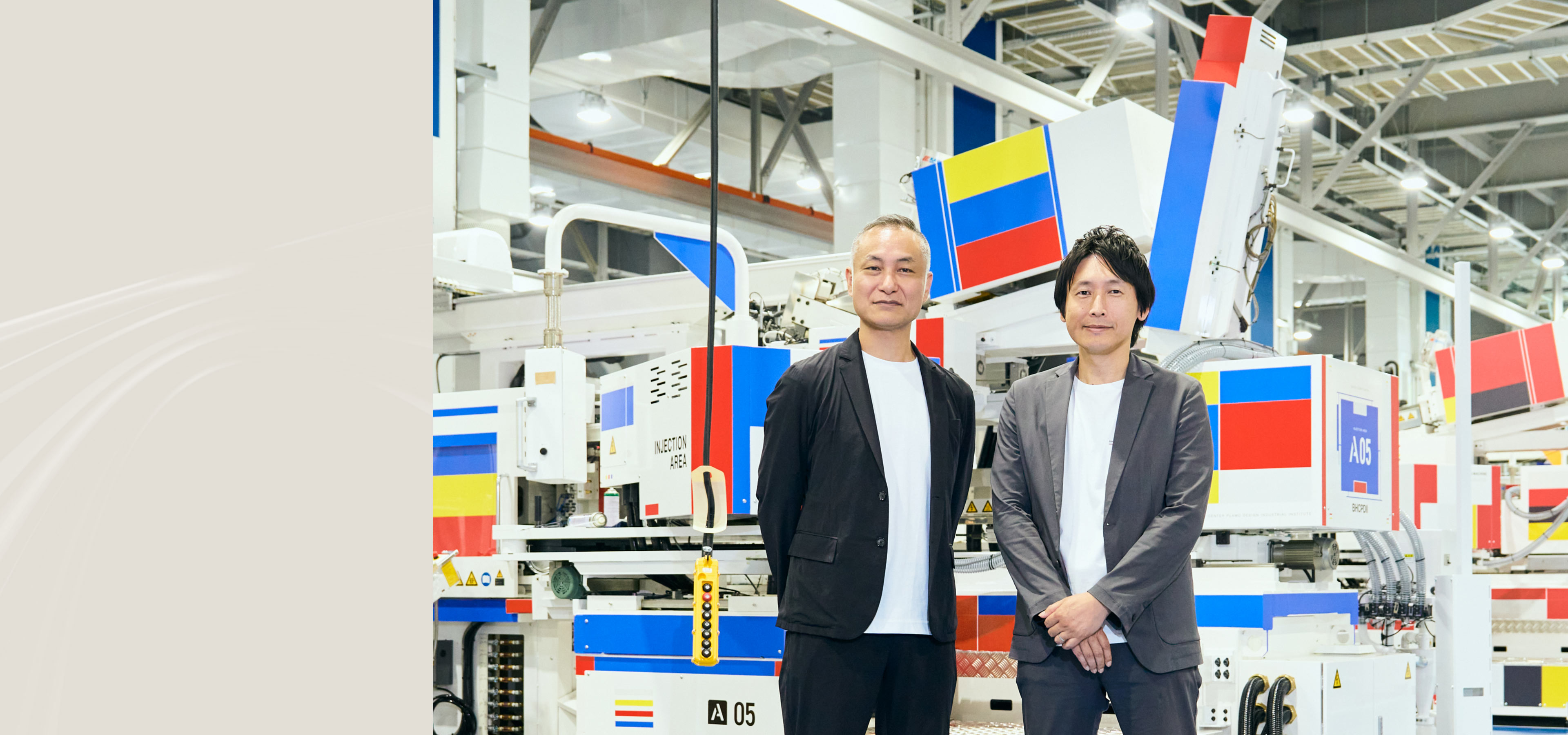

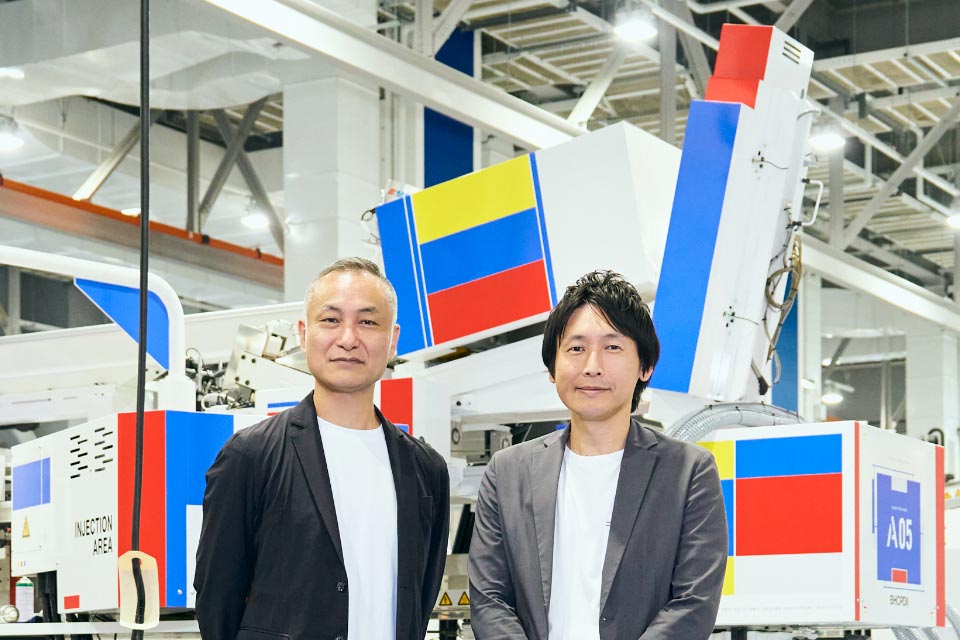

Hirotake Taguchi (left) of the Hobby Marketing Department, Hobby Products Division /

Yukio Matsuhashi (right) of the Hobby Marketing Department and Hobby Creation Department, Hobby Products Division

The commitment and spirit of workers as the foundation of creation

The history of Bandai Spirits’ plastic model business is a history of challenges in product development. Our ability to continue producing plastic models that fascinate and surprise fans is a result of the unceasing technological development and innovative concept work carried out at BHC, which have continually transformed and improved product quality.

This cannot be achieved just by having sufficient capital, such as land, buildings, and state-of-the-art facilities. No matter how advanced the machines become, the people who work in the factory are our most important asset. The foundation of our persistent creativity is the dedication and spirit of both the people who plan and develop our plastic models and those involved in every stage of the process, including design, molding, and packaging.

At BHC PDII, we wanted to convey the value of such manufacturing efforts, resulting in the concept of a "factory that fascinates."

A factory to brag about to family & friends — striving to create a space for people to gather

People are the foundation of creation, so our first focus was to create a factory that fascinates the employees who work there. BHC is not exempt from the problem of the declining workforce. In light of this, we set out to make the factory a place that employees can brag about to family and friends, thereby attracting more workers. We focused on creating a workplace where visitors will come away wanting to work here after seeing our energetic employees and their work environment.

We even designed the uniforms worn by factory workers with special attention to detail. We partnered with Tokyo University of the Arts to design the uniforms, and our factory employees themselves participated in the planning and production process. The interior design of the factory was carried out by our Gunpla package designers, resulting in a space with a distinctive look that we are proud of, rather than a standardized design. On the first floor, the molding machines are the main feature, while the third floor is designed to feel like a hotel lounge, providing workers with spaces where they can focus on their work as well as relax.

A relationship where employees and fans inspire each other

To claim to be a “factory that fascinates,” we must also ensure that the factory fascinates our fans. Since the COVID-19 pandemic, we have not been able to conduct many factory tours, which has prevented us from showing people how plastic models are made. Since BHC PDII will always be open for tours, visitors can learn about how our products are made, develop a deeper appreciation and connection to them, and come away with a stronger sense of their value. On top of that, nothing would delight us more than if visitors leave thinking they would like to work here too.

For the factory employees, it’s a motivation booster to be seen working in their new uniforms by visiting fans or to hear children say how cool they look. The ideal result would be to develop such a relationship where employees and fans inspire each other.

Delivering plastic model technology to the world — molding engineers as a dream job

We want to attract attention from all over the world as a “factory that fascinates.” Even in mass production, we want to create special products that reflect the passion of the creators, including the molding engineers. Looking ahead, we envision a future where molding engineers behind innovations in Gunpla and other plastic models are highlighted in the media around the world and admired by children as much as pro athletes, and where the products themselves that they help create carry added value.

I think Japan is a country that the world views as having a unique and interesting culture. The earnest character of the Japanese people and their strong sense of loyalty to their companies are qualities seldom seen elsewhere in the world. It is likely that Japan came to be called a manufacturing powerhouse because this national character suited the manufacturing industry, where individual technologies are honed to great depth. If we can convey these strengths to the world, we are sure to have an exciting future.

The new factory as an “institute” that will build the next Bandai Spirits

BHC PDII is different from our existing factories, and the production system will change significantly. Up to now, tasks were separated into sequential processes, from receiving raw materials to transporting them to the molding machines, adjusting molding conditions, carrying out molding, inspecting, packing, shipping, and so on.

At BHC PDII, these process-based production systems have been replaced with a single seamless production system. We switched to a function-based division of roles, where machines now handle most of the movement of objects, the inspection team carries out inspections, and molding engineers focus primarily on the skill-intensive task of adjusting molding conditions. It has evolved into an environment where each employee can leverage their own strengths.

By doing so, each and every employee will be able to deepen his or her expertise, and we expect to achieve consistently reliable quality at a higher level than ever before. Looking ahead, our aim is to share this success story and know-how across the company to further increase production volume. This is the reason behind the inclusion of the word “institute” in the name of the new factory.

Fostering manufacturing talent around the world with plastic models

Once Japan’s primary industry, the manufacturing sector is now facing a labor shortage. However, there are still likely many people out there who discovered the fun of manufacturing by building plastic models when they were very young, and who are now sustaining the manufacturing industry as adults. We want to see more people like this—people who are inspired by plastic models to become involved in manufacturing.

Currently, shipments of plastic models are divided equally between Japan and overseas. Plastic models have the potential to foster talent that will sustain the global manufacturing industry. We hope that BHC PDII will become a flagship facility in the creation of a world where more people can enjoy manufacturing.

WHAT'S YOUR “SPIRITS” Spirits at Work

For me, the spirit of our work is “grasping the essence.” In today's increasingly diverse world, I believe it is important to think through the essence of how things work and execute strategies accordingly. I try to take a big step as soon as possible, because if you grasp the essence of something at the beginning, you’re less likely to stumble.

Yukio Matsuhashi of the Hobby Marketing Department and Hobby Creation Department, Hobby Products Division

To me, the spirit of our work is “planting seeds.” The process of transforming the image of factories and plastic models cannot be measured in terms of the number of visitors, nor can it produce immediate results. Even so, in the hope that the seeds we plant today will blossom and bear fruit in a decade or two to come, we continue to devote ourselves wholeheartedly to the museum, giving particular attention to how those seeds are sown.

Hirotake Taguchi of the Hobby Marketing Department, Hobby Products Division

Affiliated departments and details are current as of the time of coverage (June 2025).

©SOTSU・SUNRISE

Related Information

Other Recommended Articles

-

Attention to Fine Detail — The Relentless Exploration Behind Adorable Chibigurumi

ChibigurumiBANPRESTOOctober 3, 2025

-

Shattering Factory and Plastic Model Stereotypes — Planting Seeds for the Future at BHC PDII Museum

BHC PDII MUSEUMPlastic ModelsSeptember 2, 2025

-

Building Plastic Models and Future Workers — Passion Behind a Factory that Fascinates

BHC PDIIPlastic ModelsAugust 20, 2025